Over time, the condition of car tires changes and this greatly affects the behavior of the car on the road. It is very important to ensure that the tires wear out evenly, if the residual is below the permissible, contact the service in time. Since it is very difficult to prevent premature rubber wear, motorists need to be able to determine its type and understand the reasons that cause this destruction. In most cases, tires wear out due to improper use.

Types and causes of uneven rubber wear

Uneven wear - damage in which a specific area of \u200b\u200bthe tire is erased. Before installing a new rubber, you need to find out the reason for the wear of the old one, because after some time, the new tires will be in the same condition as their predecessors.

|

Cause |

Damage |

Eliminations |

|

|---|---|---|---|

| Vehicle condition | |||

|

High air pressure in the chamber |

The middle strip of the tread track is erased |

Let the air out |

|

|

Low air pressure in the chamber |

The side tracks of the tread are worn out |

Pump in the right amount of air |

|

|

Car overload |

|

The side surface is torn |

Reduce the load on the machine |

|

Shock absorber problems, brake disc or violation of the shape of the brake drum |

Spots appear around the entire circumference |

Wheel balancing and / or repair of some parts |

|

|

The formation of sharp tails on one side, and on the other side, the tread bumps are unevenly erased |

Wheel alignment |

||

|

Even tire wear, but the track itself is offset to a certain side |

Wheel alignment check |

||

|

Large imbalance of the wheel, blocking when braking in a certain position |

Separate "bald patch" of the tread |

Replacing or balancing a wheel |

|

| Driving and maintenance features | |||

|

Abrupt start or braking |

|

Cracked tread |

Gaining smooth driving skills, changing tires |

|

Hitting dangerous objects |

|

Through tread damage |

Mindfulness on the road, changing tires |

|

Tire side cut |

||

|

Tire damage |

|

Bead damage during tire removal |

Using special equipment |

The most common cause of this problem is improper suspension adjustment or faulty parts. Such damage can occur after an accident or falling into a pit, changes in the geometry of the body, incorrect.

If there are any inconveniences, it is advisable to undergo a full diagnosis at a car service, where they will help to establish the exact cause of the wear.

How to determine the degree of wear on car tires?

Timely tire check reduces risk possible accident, prevents unnecessary expenses, and maybe even saves life. The most correct solution is periodic inspections at the service station. At the same time, nothing prevents you from learning how to measure the degree of wear yourself.

Tread wear rates

In the open spaces Russian Federation a uniform wear rate has been approved for motorcycles, cars and trucks 1.6 mm. There is only one exception: the tread height for light tires can be up to 1 mm. For - this indicator is very small, because if the tread depth is insufficient, the car on a wet road surface will behave unpredictably, therefore, it is necessary to change tires when approaching the 2 mm mark. For the tread height is set at 10-12 mm, so their wear can be 5-6 mm.

Tire wear indicators

Tire manufacturers, both winter and summer, provide their products with the most user-friendly and visual wear indicators. What is it - we look at the video.

Depending on the operating conditions, the same tires may fail over a different period of time. Rubber with insufficient tread depth puts the driver at risk regardless of weather and road conditions. Most attention you need to pay to check the condition of tires that are not used for the first season.

Tires are the "shoe" of the car, and therefore they also affect driving performance car. In this article we will talk about such an important topic as tire wear. And the truth is, every driver wants to know about the service life of car tires - how much tread wear is acceptable? But first, we will try to figure out what affects tire wear, how it occurs and how it can be increased.

Why do tires wear out?

High-quality and complete rubber installed on the car is a guarantee safe driving, and therefore it is strictly forbidden to ignore the condition of the tires. After all, badly worn tires can lead to a puncture of the camera or its explosion, and then the car in a matter of seconds can become completely uncontrollable, which leads to sad consequences on high speed.

Tire wear occurs gradually. This process is accompanied by the abrasion of the rubber layer, which is in constant contact with the road surface. This process is inevitable, which means that any tire has a certain service life. However, there are factors that accelerate wear and tear and lead to premature failure of any rubber, regardless of brand.

First of all, the driving style that the driver is accustomed to using during operation affects the condition of the tires. Aggressive driving has a very tangible result, which manifests itself in the form of a reduced height of the tread pattern or cracks on its surface. Constant hard braking or acceleration results in increased friction and heating of the tire, which increase its temperature, and therefore, force the rubber particles to quickly detach from the tire surface.

In addition to rapidly increasing or decreasing speed, driving at high speed through tight corners also increases tire wear, which is especially noticeable on SUVs where the differential lock is not provided. As a result, the wheels of the car enter the turn at the same speed, which also increases their friction with the surface.

Another similar wear occurs as a result of the wheels turning in place while the vehicle is stationary. Often this happens during parking, when there is no way to move and only during this process to turn the steering wheel.

Another factor of increased wear is the use of out-of-season rubber. Let's look at the example of using winter tires in summer period... The fact is that winter tires have a special property that makes them very soft, which allows them to maintain their elasticity in the cold season. On a hard road surface, such rubber heats up much faster, and therefore the wear of its surface also occurs at an increased level. In addition, riding on such rubber in summer makes the trip dangerous, as the braking distance of the car increases significantly.

The last reason for increased rubber wear is incorrect adjustment of the car's suspension. This is often observed when the deflection angles exceed the standard parameters. As a result, uneven, but accelerated wear of the tire occurs, which leads to its rapid failure. A flat tire has a similar effect, when the edges of the rubber wear much faster than its center, and the disc exerts a compressive effect and spoils not only the rubber surface, but also its shape.

Video - How to Maximize Tire Life

Car rubber service life and permissible wear

As you understand, the life of the rubber depends on many factors related to the quality of vehicle operation. If you comply with all the norms and requirements of maintenance and observe a calm driving style, then the service life automotive rubber can be approximately 5-10 years. In all other cases, this figure can be greatly reduced and then the driver will incur very large financial costs for new tires.

How to determine that rubber wear has reached a critical level? First of all, visually. The most dangerous ride on worn tires can be considered the one where the tread is almost invisible. This rubber is also called "bald". To avoid unnecessary risks, you need to know a thing or two about the tread height of your tires.

A projector is a special pattern made on the surface of the rubber to ensure the greatest grip on the road for which this tire is intended, as well as to protect the inside of the rubber from various mechanical stressmanifested in the process of contact of rubber with objects on the roadway. Tread height for summer tires should be at least 1.6 millimeters, and for winter - at least 4 millimeters. With a decrease in this value, the tire becomes unsuitable for further use and must be replaced.

Wear tolerance can be determined in many ways. The first of them is elementary measurements of the tread height using a special ruler, which are made on the most worn part of the rubber. Other methods are related to the structural features of the tire itself.

To control the condition of the rubber, special digital values \u200b\u200bof permissible wear are applied on their surface, by which the driver can judge the need to change the tire. Other manufacturers install special jumpers in the protector or color scheme wear and tear.

That's all a driver needs to know about tire wear. We hope that this article answered all your questions regarding this topic.

Engineers devote a lot of time to improving such an important part of the car as tires, since this element has an impact on the car's driving characteristics.

Each car owner perfectly understands the importance of such a structural element of any modern car like a tire. This wheel element is an elastic and durable component that is worn on car drive... The tire allows you to create contact with the road surface, damping small vibrations from the unevenness of the road and holding it securely while driving.

Any tire consists of a metal frame, internal detail tires - belts, beads with side part, as well as a slotted tread. The main material from which the cord is made is synthetic or natural rubber. The durability and running characteristics of the car will depend on the quality of the rubber. The wheel cord consists of several important elements - polymer and textile threads, and the elastic base consists of a metal frame.

Sooner or later, every car owner is faced with the fact that he has to choose new tires for his four-wheeled friend. Today there are a huge number of manufacturers and models of tires that differ not only in external and internal dimensions, but also by the material of manufacture, tread pattern and other parameters. Each parameter has a direct impact on performance and service life.

Also, do not forget that today tires are produced that have improved characteristics in certain conditions - winter, summer, all-season, high-speed. When choosing new tires for your car, you must also have an understanding of the operating conditions.

tire size and wheel rim size

All important information that is available about any type of tire is applied to the side of the wheel. This alphanumeric designation is called marking. Knowledge of these important parameters will be necessary in cases where old tires have already worn out and new ones have to be purchased, rubber replacement is required as a result of the transition to the winter or summer season, the driving characteristics of the car should be significantly improved, etc.

The inner and outer diameter of a wheel are the 2 most important indicators that are taken into account by the car manufacturer and are the recommended parameters when purchasing new tires. The inner diameter of the tire fully corresponds to the size of the rim, therefore it must be exactly observed. Also, do not forget about the outer diameter of the wheel, since these characteristics are also provided by the factory and affect traffic safety.

By installing tires with an outer diameter smaller than the stated one, you can get significant damage to the wheels, as well as worsen the driving characteristics. In the case of installing a larger diameter tires, the rubber can rub against the wheel arch liner, gradually destroying it. To avoid this, you need to consider the size of tires and wheel rims when choosing tires for your car.

tread pattern, can the tread pattern be different on the wheels of the car

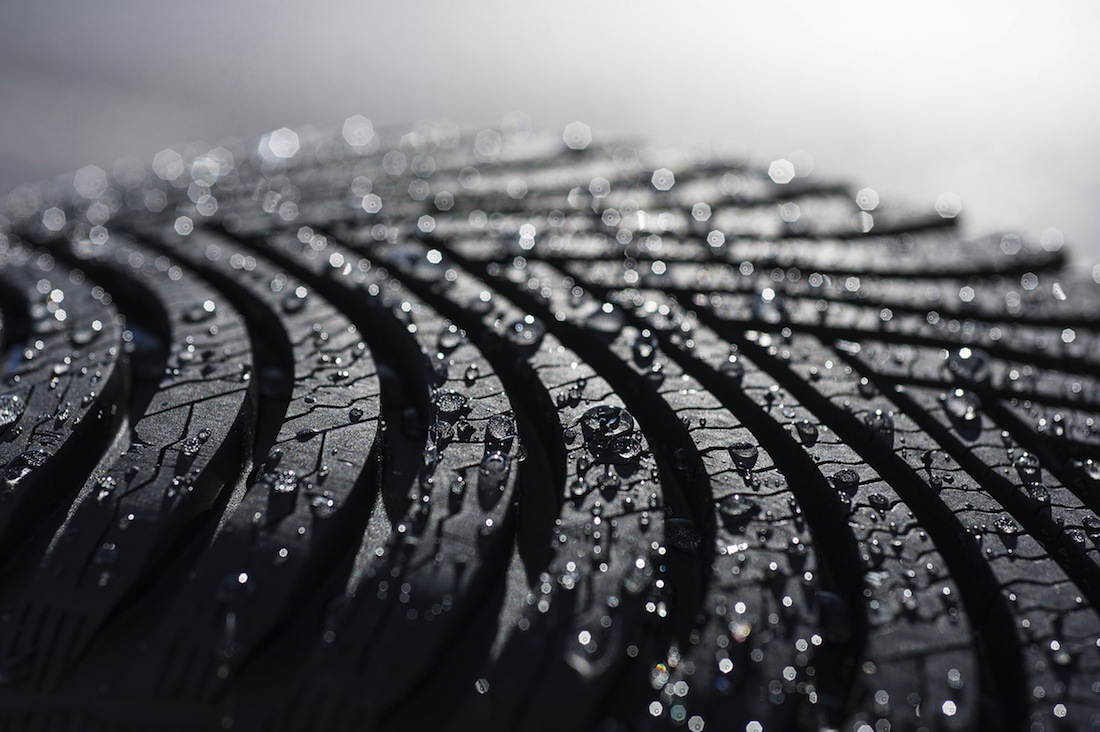

Definitely not. The tread pattern of the wheels of any car is not a decoration or a decorative part, but a complex thoughtful system of patterns on the outer side of the wheel, which improve grip on the road surface. Modern engineers and designers of car tires pay a lot of attention to this element, since it significantly improves many characteristics of the car, significantly increasing efficiency during driving and emergency braking.

Different tread pattern of tires contributes to different efficiency of water drainage from under them and improves aquaplaning of the car, due to reliable adhesion to the road surface. In addition to water, the protector helps to wick away dirt, snow, soil, etc. from under the wheels, making the vehicle more stable when driving straight ahead and when cornering. Also, a deep tread reduces the braking distance, affects the noise level in the car and gas mileage.

seasonal tires

Every car owner knows perfectly well that car tires need to be changed not only when they are worn out, but also when the seasons change - winter and summer. Winter tires differ from summer tires both externally - the tread pattern and depth, and internal characteristics - quality and material.

Winter tires are characterized by a greater tread depth and a large number of grooves. Such changes made it possible to obtain improved handling while driving on snowy and slippery roads... In addition, the tread slots are made at a slight angle, which can significantly improve traction on slippery surfaces. Tires seem to cling to unstable and loose snow, thanks to the larger number of lemeles. Over the past 50 years, the sipes have been constantly updated to improve ride comfort.

Another difference winter tires from summer is the presence of several wide longitudinal grooves, which provide effective drainage of water from under the wheels of the car. In the absence of grooves on the tires, the slots are made in the form of the letter V, each of which also helps to drain water from the road surface from under the wheels. This type of tread has become more and more popular in recent years, and it is to it that designers pay more attention. Reducing the noise level is the most important indicator.

However, the main difference is the composition of the material from which the tires are made. No wonder the rules road traffic summer tires can be changed to winter tires when the air temperature drops below 8 degrees Celsius. At low temperatures, summer tires become stiffer, which worsens road contact. A car on summer tires in winter becomes poorly controlled, and driving on such rubber entails a danger both for the transport itself and for the passengers inside.

all season tires

An all-season tire is a type of automotive wheel rubber that has properties that allow it to determine good driving performance as in winter periodand in summer. Such characteristics are not optimal for reliable driving, but only allow them to move around at any time of the year.

To date, there is no way to create a universal tire that will have excellent characteristics In any weather. Winter tires differ from summer ones not only in their composition, but also in the depth of the tread pattern. Winter tires often have a directional pattern and a greater tread depth and number of sipes. Also, the composition of winter rubber allows you not to tan at low temperatures. In turn, the summer tread has a shallower groove depth and a harder rubber that tolerates hot road surfaces well, but quickly dulls during cold weather.

All-season rubber made it possible to combine the characteristics and properties of two types of tires. The engineers combined wide slots and a large number of sipes, while using an average depth between winter and summer tires. All models all season tires wear out much faster in summer than in winter.

radial tires, pros and cons

Those who have chosen tires for their car at least once in their life have the concept of radial tires. Such tires are of the type that are installed on various types of cars. In radial tires, the cords run along the entire wheel, and this is the only design difference.

This type of tire is very easy to distinguish visually from bias rubber, since the marking of such tires has the Latin letter R. On the side of such tires, the number of cord layers located inside the rubber is indicated, as well as the material of manufacture.

All radial tires have a number of positive properties compared to bias ply. Such rubber has a high bearing capacity and is more often used as high-speed wheels. Radial tires are significantly lighter than bias tires, and have significantly greater elasticity, and are also less exposed to heat while driving. A car with this type of wheel is more stable and holds its position better while driving.

Radial wheels are most often installed on vehicles in areas where the environment is more humid. This type of tire has better contact with the road surface and also reduces the chance of puncture. A significant reduction in the weight of the wheels was achieved due to the smaller number of cord layers, since the cord of such tires takes only one type of load.

The design of radial tires was based on the use of multi-modular types of cords for the production of a belt. This allows the tread to better grip the road surface and also reduces the deformation of the tread.

Despite the many positive characteristics of radial tires, they are not absolutely ideal for car enthusiasts. This type of tire has a reduced elasticity at the side of the wheels. In the case of driving on roads with deep ruts, this type of tire can be damaged much more easily. The same reason leads to the fact that this type of wheel does not tolerate the pumped pressure.

The last and rather significant disadvantage of radial tires is their high price.

diagonal rubber, pros and cons

Diagonal rubber has significant differences from the structure of radial in that the metal cords are laid from one bead to the other diagonally, while crossing each other. Such a simple yet reliable design of radial wheels has created excellent properties for driving the car on the most difficult road surfaces.

Car tires for SUVs have a multi-layer structure, in which 6 or even 8 crossed layers can be located. This arrangement of bias tires made the wheels almost eternal. The great advantage is that they have strong side parts, while causing serious lateral damage is almost impossible. Also, bias ply rubber can significantly reduce impact loads.

Such tires have some disadvantages, including high deformation of the rubber while driving. As a result, the tread becomes shallower and the ridges begin to slip over the road. This effect makes driving less safe when driving on high speeds... Also, this type of tire can be susceptible to deformation during prolonged standing, especially when the pressure in the wheels is reduced. This distortion of the normal shape of the wheel will result in a runout of the steering wheel while driving.

tubeless tires, pros and cons

Tubeless tires are a type of car tire fitted to automobiles. different types... The process of making tubeless tires is more complex than tubeless tires. Special requirements apply to the material from which the tires are made. The material must be of better quality to ensure the tightness of the rubber against the penetration of air under high pressure.

The rubber layer must be both dense and uniform to avoid wrinkling and distortion of the wheel shape. This will significantly extend the life of your tubeless tires. The tire construction contains a special hermetic layer, the thickness of which is about 3 mm, which is attached to the inner walls of the tires.

Such wheels are inflated using a special nipple, which is tightly and hermetically cut into the car rim. For greater tightness and tightness of the tire on the rim, a special rubber band is used. Such a tape is very elastic and durable at the same time, since it experiences enormous stress during movement.

During the production of tubeless tires, nylon threads were used as a frame, which withstand high pressure, several times better than steel ones.

Tubeless wheels have a number of positive and negative characteristics that can make this type of tire stand out. When driving on tubeless tires less frictional force is exerted, while heat exchange of the wheels increases. This leads to the fact that the service life of such tires becomes much longer.

Lighter weight of such tires will have less negative impact on the car's suspension, which will reduce the cost of their maintenance. This type of tire is much easier to repair with minor damage; in some cases, the puncture can be eliminated without disassembling the wheel.

The most weak point in tubeless wheels, the side section is less rigid and can be damaged by minor stinging impacts. Very often, an air cushion forms in the tires between the sealed layer and the tube itself. Such a defect can lead to a rapid failure of the tubeless wheel.

chamber tires, pros and cons

Chamber tires are another type of automotive rubber that also have a number of advantages and disadvantages. The production of such tires is simpler, since, unlike tubeless tires, tubeless tires do not need to protect the wheels from passing high pressure of them.

The main advantage of these tires is their relative cheapness in comparison with tubeless tires. This was achieved through a simplified design. They are protected from side cuts, in which it will be sufficient to replace only the inner air chamber.

The main disadvantage is that even a small cut or puncture of the wheel will lead to a gradual decrease in air pressure. In this case further movement can only be done after complete replacement tires or cameras. These tires are heavier than tubeless tires, and patching minor injuries is more difficult than tubeless tires.

tire brands

Today on automotive market You can find a huge variety of different brands of tires that can fit almost any car. The average consumer who first chooses a new rubber for their four-wheeled friend can very easily get confused by the variety of brands.

In fact, all brands can be relatively divided into several categories, some of which originate from the moment the first cars appeared. Today, most of these companies represent huge factories with multi-million circulations that have gained vast experience in the production of wheels all over the world. Such tires are most often of the highest quality, reliability and durability, but their cost is much higher than other brands.

This group includes such brands as Continental, Michelin, Goddyear, Pirelli, Bridgestone and some others. Brands such as Nokian and Hankook should also not be overlooked.

The second most popular group is the subsidiaries of the most popular wheels. The distinguishing feature of such companies is their focus on domestic marketbecause these brands are less weighty and famous.

The third group is occupied by brands that are gradually entering the market, but managed to surprise many car owners for high quality products. Most of these companies are located in Korea, China and Taiwan.

Thus, today in the world there are a huge number of companies that are engaged in the production of tires for cars. And who will become more in demand in this race, time will tell.

How to find out the correct tire pressure

Tires are one of the main elements that keep the car stable on the road surface. However, it is the correct pressure in the wheels that allows you to normalize fuel consumption, increase the stability of the car while driving, and also increase the operating time. In addition to these characteristics, the correct pressure will affect driving safety as well as eliminate wheel breakdowns. In order for the tire pressure to be optimal, they need constant monitoring. Experts and experienced drivers recommend checking the tire pressure every time you refuel the car.

Incorrect tire pressure can cause the tire tread to wear unevenly, leading to rapid tire failure.

In order to check the correct tire pressure, you must use special device - pressure gauge. Such a device can be purchased at any car store, as well as at any station. maintenance... The pressure gauge is part of any compressor that inflates the wheels.

Checking the tire pressure should be carried out on slightly cooled wheels, however the best option will become frozen in the morning or before the start of the trip. Since during intensive driving, the tires are heated and, accordingly, the air inside gradually begins to expand, which will lead to errors when checking.

Each wheel has a special air valvethrough which air is pumped. In order to measure the pressure, it is necessary to unscrew the protective plastic cap, and then put the pressure gauge on the valve. While screwing on or putting on the gauge, a small sound of air escaping from the wheels will appear, at the same time a pressure reading will appear on the gauge.

The manufacturer issues the recommended tire pressure parameters for different vehicle loads. After measuring the pressure, it is necessary to compare it with the recommended figures and, if necessary, inflate or reduce the pressure inside the tire. It is possible to bring the pressure in the wheel to normal using a compressor, hand or foot pump, or a compressor.

Thus, the pressure in each wheel is checked and brought to the same recommended value. After checking, put the protective cap back in place.

how often should the tire pressure be checked

Experts recommend checking the tire pressure regularly. The most correct thing would be to control at least once a month, as well as before the planned long trips and after them. Tire pressure not only leads to increased consumption fuel, but in addition to this, the tire tread will have uneven wear. This is one of the clear signs of incorrect tire pressure that can be visually noticed.

Even during an ideal and quiet ride, the tire pressure can gradually decrease by about 0.65 bar per month. However, in hot weather, when the temperature of the asphalt rises significantly, the rate of pressure drop can accelerate significantly.

How to check the degree of tire wear using coins, 2 rubles and 10 rubles

Driving a car has a large number of nuances that can affect the safety of all passengers. One reason is the degree of tire wear, which must be monitored continuously. Unfortunately, many drivers have no idea how to properly conduct this control, therefore you need to do it using improvised methods. You can diagnose the degree of wear of car tires using a regular coin.

In Russia, 2 and 10 ruble coins are most often used for these purposes, in the absence of a special measuring instrument... The coin should be placed in the protector with the head of the emblem pointing down. If the eagle's head barely touches the tread level, or is more submerged in it, then such wheels are still in good condition... Otherwise, you need to think about replacing the rubber.

Tread wear depending on climate and mileage

Each car tire has its own service life, during which they are influenced by a large number of various factors. Climatic conditions and mileage are the main causes of tread wear.

![]()

Each tire has its own margin of safety, which is determined not only by the quality of the material used, but also by the size and season of use. The safety margin is approximately 30,000-70,000 km. The tire is influenced by various factors: significant overload of the car by weight, under-inflated or over-inflated tires, poor wheel mounting, malfunctions in the steering and running gear, wheel imbalance, climatic conditions and driving style.

Each of these causes accelerated wear and tear and leads to premature replacement.

Tire wear indicator

The tread depth is one of the most important indicators that affect the safety of a car. The tread depth also has an impact on the vehicle's handling, traction, fuel consumption, etc. Therefore, this parameter must be constantly monitored, which can be achieved with the help of diagnostics and visual inspection.

However, modern tire manufacturers have developed a system that can be used to inspect the tread depth of a tire. For these purposes, special indicators were built into the tires, having the form of a convex pattern on the surface of the tires, or a digital indicator.

Volumetric indicators represent the simplest form of information about the degree of wear, and the information content and data accuracy are at a high level. Gradually wearing out, the tread depth becomes smaller, which can be tracked using a special indicator. Thanks to them, the driver will be aware that tire wear is critical and that it is necessary to take care of wheel replacement.

Digital indicators have a different device and, in contrast to volumetric ones, are squeezed out in rubber. They have different depths of penetration. Most often, the number 8 represents the shallowest tread depth, while the number 2 for summer tires and 4 for winter tires represent the minimum tire wear.

What does the accident statistics say about the impact of tread depth less than 4 mm on accident rate

Automotive rubber manufacturers conduct constant research on quality as well as traffic safety in various conditions. The most optimal tread depth of a car's rubber is more than 5 mm. This depth has no practical impact on the formation of emergency conditions. With a decrease in depth to 3-5 mm, the risk of getting into an accident increases by 10%.

If we talk about the depth of the drawing 2-4 mm, then the accident rate increases by another 10%, in contrast to the deeper drawing. 2-3 mm of tread depth have a significant increase in the possibility of getting into an accident, which is 20%. With more "bald" car tires, the operation of transport is not recommended and, moreover, is a violation of traffic rules.

The minimum tread depth of summer and winter tires

When choosing a new automobile rubber, it should be understood that the tread depth for asphalt roads should be 7.5-8.5 mm. This depth is sufficient for normal and safe driving. In the case of buying tires for off-road vehicles, the depth of the pattern should be significantly deeper and equal to about 17 mm.

In 2015, the minimum standards for the tread depth of a passenger car were changed. It is now prohibited to operate the vehicle with a tread depth of less than 1.6 mm. These characteristics and requirements apply to both summer and winter tires. However, the recommended figure by experts is at least 2 mm, below which driving on the car will be unsafe.

Experienced drivers recommend closely monitoring the depth of the winter tire pattern much more carefully. Since the contact of the car with the surface road surface deteriorates, so the tread depth must be at least 4 mm. It is this depth that reduces the risk of falling into emergency and improve vehicle handling.

Decoding of tire marking

Each car tire manufacturer has its own tire names that convey important information about the characteristics of tires to the end consumer. For example, very often in the names of winter tires, the word ICE can be found, which will inform about their belonging to winter driving.

Decreasing the tread depth will increase the braking distance on wet roads. Tires with inadequate tread depth can cause aquaplaning even at low speeds. For this reason, tires must be replaced as soon as possible before the tread wear indicators are visible. The presence of these indicators, which are raised 1.6 mm from the bottom of the tread pattern, is mandatory in accordance with international safety regulations.

TWI - Tread wear indicator - sign on the sidewall of the tire - shows the location of the marks of the residual height of the pattern in the tread grooves. The mark is applied on the sidewall at the very edge of the tread evenly in six places around the circumference on each side of the tire. The label can be either the aforementioned abbreviation - TWI, or TWI with an arrow, or just an arrow without letters.

However, the TWI mark is only an indication of the location of the wear indicator itself. The tread wear indicator itself must be looked for at the bottom of the tread groove closest to the mark (if there is an arrow, it indicates this groove). There, looking closely, you can find a rubber protrusion, its height is 1.6 mm from the bottom of the groove - this is TWI. It shows the maximum permissible degree of tire “balding”. When the tread wears off to this protrusion, the rubber must be changed without fail.

However, the TWI mark is only an indication of the location of the wear indicator itself. The tread wear indicator itself must be looked for at the bottom of the tread groove closest to the mark (if there is an arrow, it indicates this groove). There, looking closely, you can find a rubber protrusion, its height is 1.6 mm from the bottom of the groove - this is TWI. It shows the maximum permissible degree of tire “balding”. When the tread wears off to this protrusion, the rubber must be changed without fail.

When the residual height of the tire tread approaches the specified minimum value, the value braking distance when driving on a wet road increases. A film of water between the tire and the road can cause a loss of contact with the road surface, even at relatively low speeds, and create a loss of control situation known as aquaplaning. Taking this into account, it becomes important to recommend timely replacement of tires, and it is best to do this before reaching the residual height of the tread pattern. In all countries belonging to the European Community (EEC) and in the Russian Federation, it is required that the residual tread height of tires for passenger cars was equal to at least 1.6 mm.

Drivers tend to overestimate the condition of their tires. To avoid inaccurate assessment of the condition of tires "by eye", nokian Tires has developed a special DSI (Driving Safety Indicator) wear indicator that allows you to accurately estimate the residual tread depth. The DSI system displays the depth of the tread groove in millimeters. The value shown allows you to clearly determine whether the tire meets the safety requirements and how deep the residual tread depth is.

On MICHELIN tires for example, a Mr. Michelin figure on the sidewall of a tire indicates the location of the tire wear indicator, which is located in the main tread grooves. Indicators are also protrusions at the bottom of the tread grooves.

Even if the depth of the projector is more than 1.6mm, the driving speed and driving style must be selected according to road conditionsespecially on wet roads. On winter mICHELIN tires the location of the wear indicators is indicated by a snowflake icon. The height of the wear indicator is 4 mm.

For optimal grip on snow, which is necessary for both braking and traction, change winter tires follows when the projection of the wear indicator is flush with the tread surface.

Alternatively, an arrow may be used instead of a letter designation, and Michelin uses its own brand name for this.

The natural aging of the tire, which is the result of physical and chemical processes and negatively affects its performance. This applies even to tires that have little or no use. Many factors affect the life of a tire: temperature, maintenance, storage and operating conditions, load, speed, pressure, and driving style. These factors also affect the operating life of the tires. It is recommended that all drivers inspect tires regularly and check for obvious signs of aging or fatigue. Such marks include cracks on the outside of the tread, shoulder and bead zones, deformation, etc. Tires with signs of excessive aging may not provide the necessary grip.

After five years or more of tire use from the date of manufacture, it is recommended as a precautionary measure to replace them with new tires. This must be done even if their condition appears to be satisfactory and the tread wear has not reached the indicator level.

The main goal of road safety is to reduce accidents. Meanwhile, ruthless statistics claim that a huge proportion of road traffic accidents are due to neglect of the condition of cars. Any driver, no matter how experienced and careful he may be, should know the axiom - the tires are bald, replace them with a new one. Many car owners, especially those with little experience in operating a car, often ask how to determine tire wear? Let's look at several ways.

The easiest and most accurate way to check tire wear is to use a tire gauge.

Permissible tire wear is the minimum tread height at which it is safe to drive a passenger car. It is registered in the SDA and is 1.6 mm. But, as you know, there is a difference between a tire and a tire, so this assumption cannot be true for absolutely any tire. Therefore, drivers who have been operating their cars for many years in different weather conditions and on different surfaces, brought out something different " golden Rule»- the tread depth must be at least 2 mm in summer and 4 mm in winter.

Tread gauge as the easiest way to check

Nowadays, on store shelves in a large assortment there are so-called tire tread gauges. Anyone can use them, since there are versions of devices that will not only show the numerical value of the height of the picture, but also tell you whether it is time to change the tires. Simply place the gauge on the wheel (or rather, insert the dipstick into the groove) and it will show the residual tread depth.

"Engineering" way

The first thing that comes to mind to measure the tread depth for people with a technical mindset is a ruler or a caliper. Insert the caliper probe into the tread (at the bottom of the groove) and observe the reading on the gauge. Also, this operation can be done by using some kind of pin (for example, a match) and a ruler instead of a probe. If you have experience with a measuring tool, then it will not be difficult to measure the tread using a ruler and vernier calipers.

Checking the depth "from the manufacturer"

Bus with TWI indicator

Often, self-respecting manufacturers such as Michelin or Nokian use a tire wear indicator, that is, they imprint numbers on the tread surface. As a result of the operation and wear of tires, numbers are also erased. These numbers mean the remainder of the figure in millimeters. Thanks to this landmark, you can easily replace worn-out tires at the very moment when they completely waste their life and become unsafe.

Another way the manufacturer cares about the safety of their products is to indicate the normalized mileage for each of the models produced. Unfortunately, these numbers cannot be relied on. The "mileage" of a tire has a very large dependence on the following factors: operating conditions, driving style, vehicle weight, suspension serviceability and even the type of transmission (mechanic or automatic). The accuracy of this method is plus or minus 10 thousand kilometers.

Also, special wear indicators - TWI are used on the tires. This type of indication is quite common and is a narrow strip that is applied to the tires between the tread blocks. To notice this control device, you should look closely at the side of the tire. You can see either the logo of the manufacturer, or its name, or an arrow. If this sign comes in contact with the road, the rubber should be replaced with a new one.

Some manufacturers offer to monitor tire wear with a digital indicator.

"Handy" way with a coin

Drivers of all countries are distinguished by their sense of humor, so they came up with an easy and positive method for determining the degree of wear of the tread. It is based on measuring its height with a one dollar coin. It is done like this: a coin with the image of the president is inserted into the protector so that his head is directed downward. Pay attention to Washington's hair. If they are visible, then the tires can be changed.

If there is no metal dollar, maybe there will be a cent? If so, then Lincoln will come to your aid. With the same scheme as with Washington: the top of Lincoln's head, accessible for contemplation, speaks of a desirable change of tires; if God only favors rubles and a penny, do not despair. A proud eagle from a two-ruble coin will help you. Send a coin, eagle head down, into the protector. Head over tread - change the rubber, head in the tread - the tire will still work - oddly enough, this method is quite common. Probably due to the fact that any car enthusiast has a trifle.