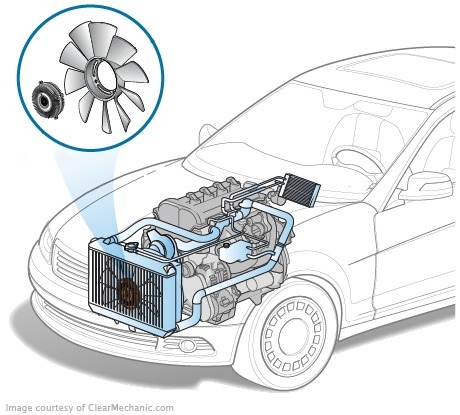

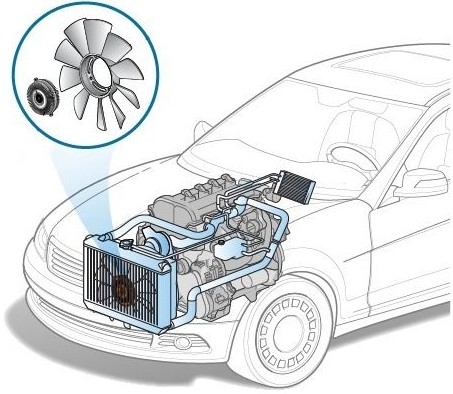

Today I would like to talk about the principle of operation of the radiator fan. Its blades are positioned in such a way that the air supply is more massive, and the cooling, respectively, more efficient. For this, the blades, of which the fan has at least four, are located on a common pulley, at a certain angle to the rotation area.

The type of radiator fan depends on the type of drive. Exists:

- mechanical;

- electrical;

- hydromechanical.

Radiator fan mechanical drive

Radiator fan with mechanical drive - from crankshaft, by means of a belt drive, is carried out permanent drive... This option has a serious drawback, such as high cost motor to make the fan rotate. Therefore, car manufacturers have almost completely abandoned such a fan drive.

Radiator fan electric drive

A radiator fan with such a drive has its own principle of operation, perhaps the most common in modern car manufacturing. This cooling mechanism includes an electric motor and a control system. The electric motor itself is powered by an automobile on-board network... The intelligent control system automatically calculates the operation of the radiator fan, focusing on the degree of engine heating. In many modern carson mobiles, a controlled fan run-out function already exists. This is done so that after stopping the car and turning off the engine, the fan would blow on the engine. The control system will select the "cooling" mode independently, based on the degree of heating of the car engine.

The circuit for switching on the electric motor of the fan of the engine cooling system of the VAZ 2107 car:

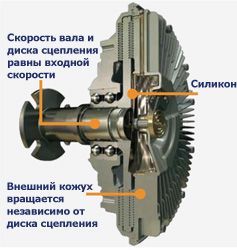

Hydromechanical radiator fan drive

Such a drive at a car fan can be a hydraulic clutch or a viscous clutch. As for the latter, here the permanent drive is carried out by a crankshaft. The sleeve can be blocked with silicone fluid inside it. As the engine heats up, the crankshaft speed increases, the clutch can be blocked, either completely or partially, and this action will start the fan operation. The hydraulic clutch contains oil inside, the volume of which depends on the degree of heating. When will happen desired change the contents of the clutch, it will again be blocked, and the cooling mechanism will start automatically.

Concerning typical scheme control of an electrically driven fan, it includes the following elements:

- Coolant temperature sensor, which records the temperature of the coolant. I must say that there can be several such sensors on one car. One is installed at the outlet of the radiator, and the other at the inlet. Based on the difference between the readings of these sensors, the fan will be controlled.

- Relay for turning on the fan.

- Electronic engine control unit.

- Electric motor.

These signals go to the electronic unit motor control. After the information has been processed, the radiator fan relay can be activated.

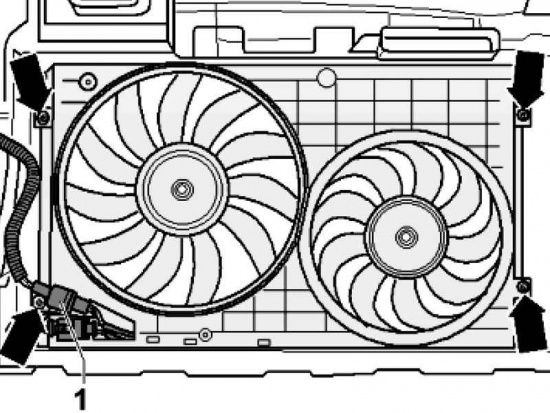

In those vehicles that are equipped with a towing device or an air conditioner, as a rule, 2 fans are installed at once, which can work both separately and simultaneously. Everyone has it car fan there is its own relay.

AT modern world more and more often they began to use the fan control unit instead of the fan switch on relay. It ensures economical and efficient operation of the cooling device.

In any engine internal combustion there must be an effective cooling system. Without which the motor will overheat and all its moving parts may fail. Modern cars equipped with a cooling system in which coolant circulates. The circulation is carried out using a special pump - a pump. Any coolant begins to boil with long-term heating. To prevent this, a radiator is provided in the cooling system. The engine cooling radiator consists of many thin tubes, to which special lamellas are attached to increase the cooling area. When the car is moving, air passes through the radiator fins and cools the metal, thereby reducing the temperature of the coolant. But at low speeds or when standing in a traffic jam, the radiator is not able to resist engine overheating alone. In such a situation, an electric fan comes to the rescue, which is activated automatically at a certain temperature of the coolant. If the cooling fan fails, the motor will overheat. Next, we will look at why the radiator fan does not turn on, as well as possible reasons and the malfunctions that lead to this and methods of their elimination.

What is an electric radiator fan?

The car cooling fan is a conventional electric motor that is powered by the car's on-board network. An impeller is attached to its shaft, which directs a strong air flow to the radiator, to the front of which it is attached using a special frame. The cooling system is equipped with a fan diffuser for more efficient operation. Most cars have one fan, but there are cars with two independent impeller electric motors, which turn on at the same time. Two fans are installed in order to cool the motor faster.

How does the fan turn on?

AT different models car device starts up differently. The carburetor engine has a fan switch sensor that sends a signal to the relay after the liquid heats up to the set temperature (100-105 ۫). Then the fan relay is activated and energizes the electric motor. AT injection engine control is carried out using an electronic unit, which first analyzes the information received by the controller, and then transmits it to the relay.

Possible malfunctions of the electric fan

When the coolant temperature is critically high and the radiator cooling fan does not turn on, then there is a problem somewhere. Our task is to define it and fix it. Some common reasons for fan failure include:

- Breakdown of the electric motor;

- Open circuit in the fan power supply or switch-on sensor;

- The contacts of the sensor or motor connection are oxidized;

- Blown fan fuse;

- The fan off relay has broken;

- The inclusion sensor is out of order;

- Expansion tank valve defective.

How to check the radiator fan

The very first thing, if the cooling fan fails, check the fan drive motor. To do this, you need to take two wires and connect them directly from the battery to the electric motor. If it works, then the problem should be looked for in something else. You can immediately check the quality of the contacts of the electric motor connection. Sometimes it happens that they oxidize or get dirt and dust in them. If the electric motor does not start after connecting it directly, it is most likely out of order. The cause of the malfunction may be worn brushes of the electric motor, replacing which will solve the problem. There are breakdowns, and more serious, for example, winding breakage, destruction of the collector. In such a situation, repairing the radiator fan will not help; it is necessary to replace the radiator fan.

Checking the wiring

Faulty electrical wiring is another of the most common reasons why the electric fan of the engine cooling system may not work. The wiring can be either open or short to ground. The integrity of the wiring is checked using a tester, which is set to detector mode. It is necessary to "ring" the entire circuit, from the engine to the relay, from the relay to the fuses, from the fuses to the controller, from the controller to the sensor. If everything is in order with the wiring, proceed to the next stage of verification.

Checking the health of the fan start relay and fuses

First, we check the fuse of the electric fan. It is usually located in a block under the hood of the car. You can find the correct fuse using the car's owner's manual, although often on the cover mounting block there is a marking with the location of the fuses. We carry out the check using a tester. If no malfunction is identified, go ahead. We find the relay for turning on the electric fan. You will not be able to check it with a tester; to check it, you will need to replace this relay with a working one.

Checking the sensor for turning on the electric fan

One of the reasons for the failure of the electric fan may be a sensor breakdown. It is possible to establish with accuracy that it was the fan switch-on sensor that failed, only on the injection engine. When we disconnect the sensor from the power supply, the control unit starts the electric fan in emergency mode... To check, warm up the engine to a temperature of about 100 ۫C, then turn off the engine, raise the hood and disconnect the sensor from the network. Then we turn on the ignition and, if the fan starts up, then there is a breakdown in the sensor for turning on the electric fan. On a carburetor engine, check that the sensor is working properly; you can only replace it with a new one. After that, it is also necessary to warm up the engine until the radiator cooling motor starts.

Replacing the safety valve radiator barrel

One of the causes of malfunctions in the cooling system is the failure of the radiator reservoir safety valve. It is worth checking the serviceability of its work, if it fails, only its replacement will help.

Continuous operation of the electric cooling fan

One of the problems that a car enthusiast may face is the continuous operation of the cooling fan. If the fan starts up very early, when the temperature of the liquid has not reached the working temperature, or does not turn off at all, the cause of the breakdown should be found and removed. Here are some reasons permanent work fan:

- Sticking relay contacts. In this case, the fan motor will start as soon as the ignition is turned on;

- Sensor problems. If the fan starts to start earlier than expected, the fan switch sensor is often faulty. It needs to be changed;

- Thermostat does not open. In this situation, the coolant does not enter the radiator and quickly overheats, which forces the electric fan to turn on. And since the liquid does not reach the radiator, its temperature will not drop and the fan will operate continuously.

However, the continuous operation of the electric fan is not as dangerous as its failure completely, but not in the third case, when the thermostat is jammed.

Check regularly that all components of the engine cooling system are working properly. Watch the readings of the coolant temperature on the dashboard, listen to if the electric fan starts. Check that the coolant level is correct. In due time, replace the coolant. Keep the cover of the expansion barrel clean and rinse it under running water at least once every six months. This will help extend the life of the safety valve.

In case of any malfunction in the engine cooling system, it is necessary to stop and take measures to eliminate them. If the radiator fan thermal switch, fan relay or fuses are out of order, to continue driving, you can connect the radiator cooling motor directly to the battery, in the case of carburetor engine, and on the injection motor, it is necessary to disconnect the power supply of the electric fan sensor from the on-board network. This way you can get to the station maintenance do not overheat the engine.

There is no need to say once again about why an engine cooling fan is needed and what its malfunction is fraught with. As the name implies, its main purpose is to cool the engine while the car is in motion. Often this device fails, there are a lot of reasons for this, let's deal with the main points of repair.

Engine cooling fan: principle of operation

First of all, you need to understand how this device works. Since we are dealing with a whole set of mechanisms and devices that allow heat to be removed from the engine to environmentthen this is a rather complex system. In this article we will be talking about air cooling, not liquid cooling. The fan is installed between the cylinders. It is driven by a V-belt drive directly from

The engine has special shrouds that allow air to be directed to those parts of the engine where the temperature is highest. Fan consumption is 8-9% of the maximum. Do not forget that it turns on and off automatically when a certain temperature is reached. For example, the cooling fan of the VAZ-2110 engine starts to work when heated to 95 degrees Celsius and above. If this does not happen, then you need to look for the cause and eliminate it.

Finding the problem

As practice shows, it is not always as easy to find the cause of a malfunction as it might seem. The most common failure is failure at the right time. That is, the engine warmed up to a maximum temperature of 95-99 degrees, and the device does not turn on. In this case, we need to open the hood and find a thermal switch, usually located on the side of the radiator. It can be replaced or attempted to be repaired.

Of course, breaking a thermal switch is not the worst thing that can happen. Failure of the fan motor is much worse. Firstly, the repair is more time consuming, and secondly, it may not be of any use. But, first of all, you need to check the electric motor, as it could fail. If it is ok then try the following. We disconnect the wires from the thermal switch and connect them together, turn on the ignition. The fan should start working. Thus, the breakdown is not caused by the electric motor, but by the switch.

Repair tool

So, you checked everything, went through every fuse and already got to the relay, but the problem was not solved. Therefore, the engine cooling fan does not work, and the motor of the device must be removed and repaired. For this we need minimum set tool. We take 10, almost everyone has this in the garage, you will also need an extension cord, medium or long.

It is advisable to have a ratchet. If you don't have one, you can take a regular crank. Also, prepare a rag, as this is a dusty job. It is best to have a flat and Phillips screwdriver and a set of keys at hand. That, in principle, is all, then you can proceed directly to dismantling the device. By the way, before starting work, it is advisable to disconnect the mass of the battery, that is, "minus".

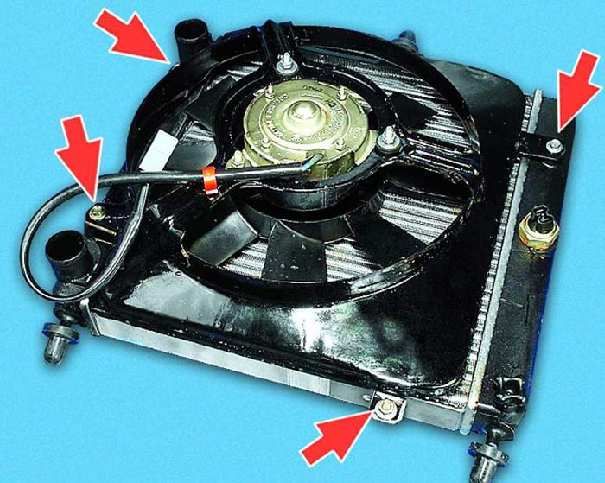

Remove the engine cooling fan

After we have necessary tool, the machine is installed on a horizontal surface, and the ignition is off, you can proceed to dismantling. First you need to completely disconnect the wires going to the fan. First of all, we pull out the motor plug, and only then the temperature sensor wires. Only here there is one nuance, you need to disconnect both ends, that is, from the sensor and the fan.

Next, the engine cooling fan is ready to be removed. But before that you need to unscrew all the bolts. First, we unscrew two of them, those that are located at the top and bottom, as a result, we get a free left side. As for the right one, there is only one bolt in the center. The next step: we take the fan in the center and pull it towards ourselves, you need to get it out from under the hood without any effort.

A little about repair

It is worth noting that the device is completely collapsible. Therefore, it must be replaced as a complete unit. However, in some cases it makes sense to do dIY repair... For example, a winding in an electric motor has shorted. Problems are even simpler, such as a blown fuse. You just need to change the part, and everything will work.

It is worth noting that the engine cooling fan, the price of which is rather big today, must be periodically cleaned. After we remove it, we need to clean it from various kinds of dirt with a brush, this can improve its performance. Since this device has several speeds, a special resistor is used through which current is supplied. There is a fuse there, which quite often blows, because of this, in fact, the fan may not turn on.

Checking the electric motor and wiring

During the operation of the car, the wires oxidize, as a result of which the contact becomes worse. Therefore, before changing anything, you need to look at the state of the wire. Unsuitable ones must be replaced immediately or cleaned with a brush. But if the problem still remains, then you will have to check the fan motor. It is quite simple to do this, now you will find out how.

If the engine cooling fan does not turn on, then we do the following manipulations. First, you need to disconnect the plugs of the wires, and then a jumper is installed between the contact of the black and red wire and the positive of the battery. Next, using the second jumper, connect the brown wire terminal and minus battery... After that, turn on the ignition, the fan should work. If this did not happen, then we have a faulty electric motor. In this case, you can try to carry out repairs, but it will take a long time and it is not known what the result will be.

The engine is hot and the fan does not turn on

This is perhaps the most common problem. We have already said a little about this at the beginning of the article, but here you need to understand in more detail. For example, the engine cooling fan "Kalina" should turn on at a temperature of 99 plus or minus 2 degrees. The device should turn off at a temperature of 92 plus or minus 2 degrees. If this does not happen, for example, it turns on but does not turn off or vice versa, then repair or replace the thermal switch.

To check if this is the case, you can try to start the engine, let it warm up to operating temperature, carefully unscrew the lid and put a thermometer in there. If the mark stops between 92 and 99 degrees, then the first speed should turn on, if at 99-105, then the device should work at the second speed. If any deviations were noticed, then most likely the fuse on the resistor has blown.

Repair of rotor and brushes

Sometimes banal dirt is to blame. For many years, the vehicle has been in operation and its systems are not cleaned. As a result, we get a malfunction. As an example, let's consider the cooling fan of the VAZ-2110 engine. To carry out repairs, you need to bend the motor cover and look at the general condition of the equipment. As a rule, replacement of brushes is required due to the environment in which they are used. They wear out quickly, get dirty and do not cope with their work.

As for the rotor, there are few options. The first step is to check if the winding is working. If everything is in order, then we can rejoice, we will not have to change it. If there is an open circuit or short circuit, then we begin to sort out each loop and look for where the problem is. You also need to clean everything of dirt, and there will be, believe me, a lot of it. To do this, you can use a metal brush, as well as a rag. The use of solvents without chemically aggressive components is allowed.

As for the rotor, there are few options. The first step is to check if the winding is working. If everything is in order, then we can rejoice, we will not have to change it. If there is an open circuit or short circuit, then we begin to sort out each loop and look for where the problem is. You also need to clean everything of dirt, and there will be, believe me, a lot of it. To do this, you can use a metal brush, as well as a rag. The use of solvents without chemically aggressive components is allowed.

Conclusion

Let's summarize. We figured out how to fix the engine cooling fan. If you can't do it yourself, then you need to go to the service, but the pleasure is not cheap, and you can be charged 5,000-10,000 rubles. Of course, if you lubricate the rubbing surfaces at least once every few years, clean the blades from dirt, and change the fuses, then many problems can be avoided. Nevertheless, no one is immune from breakdowns, but now you know how most malfunctions are eliminated, especially since engine cooling is not so difficult. You just need to make a little effort, have the necessary tools and new parts. If you do everything yourself, you can save up to 60-80% of your money.

Engine cooling fan - a device that allows you to forcibly blow off a heated engine and a radiator of the cooling system when the car is parked with the engine running.

The role of the fan in the cooling system

The process of evolution of the cooling system initially followed two main paths, so they found application in production cars: air cooling and liquid (or rather, hybrid). The fan is used in both types of cooling systems, since the final carrier that dissipates the heat removed from the engine is air. The fan acts as a device that ensures constant and even heat dissipation into the atmosphere.Types of engine cooling fans

During the development of the cooling system, there were only two efficient fan designs. The first type is a mechanical fan with a belt drive from a pulley mounted on. To ensure the safety of the blades when high speed rotation of the crankshaft, the fan impeller is connected to the pulley through a hydromechanical drive, which, depending on the design, is called a thermal coupling or a fluid coupling.More often car engine equipped with an eight-bladed impeller, although the number and shape of the blades are not regulated anywhere

This device is a version filled with a silicone gel that changes its properties upon exposure to temperature. The degree of clutch lock affects the fan speed. When the engine spins, the clutch begins to "slow down" the rotation of the impeller, which would inevitably break at a rotation speed of 3000 rpm and above. The thermal coupling and the hydraulic coupling differ from each other in design and principle of operation, but both of them allow you to keep the speed of rotation of the impeller within narrow limits, allowing it to accelerate and decelerate only as much as necessary for effective heat dissipation, and no more. components and the beginning of their application to control processes in the engine, appeared and quickly gained popularity. The drive consists of an electric motor and a control system that controls the intensity of the cooling fan depending on the readings of the temperature sensor. The use of electronics made it possible to bring the uniformity of engine cooling to a new qualitative level in comparison with the inert "analog" system based on viscous coupling.

The device and principle of operation of the engine cooling fan

Viscous fanFans with a viscous coupling nowadays are found on passenger cars seldom. Their use is limited to models with longitudinal arrangement engine, and even then, convenience electronic control gradually reduces their use to nothing. The only segment in which the installation of a belt-driven fan is preferable is serious off-road vehicles such as UAZ or those designed to boost water barriers... Electronics is afraid of water, and the viscous coupling is hermetically sealed, and will not fail after "bathing". The coupling is filled with silicone oil, the volume of which is approximately 30-50 ml. Fan with electronic control unitFan mechanism with electric drive includes: an electronic motor control unit, a temperature sensor, an electric motor and a fan relay. On modern cars, two sensors are increasingly being installed that record the temperature of the coolant. One of them is built into the radiator outlet, the other into the engine outlet or thermostat housing. In this case, the fan is controlled based on the difference in the readings of these sensors.

Viscous fanFans with a viscous coupling nowadays are found on passenger cars seldom. Their use is limited to models with longitudinal arrangement engine, and even then, convenience electronic control gradually reduces their use to nothing. The only segment in which the installation of a belt-driven fan is preferable is serious off-road vehicles such as UAZ or those designed to boost water barriers... Electronics is afraid of water, and the viscous coupling is hermetically sealed, and will not fail after "bathing". The coupling is filled with silicone oil, the volume of which is approximately 30-50 ml. Fan with electronic control unitFan mechanism with electric drive includes: an electronic motor control unit, a temperature sensor, an electric motor and a fan relay. On modern cars, two sensors are increasingly being installed that record the temperature of the coolant. One of them is built into the radiator outlet, the other into the engine outlet or thermostat housing. In this case, the fan is controlled based on the difference in the readings of these sensors. An electrically driven fan with a thermal switch can be installed on almost any car engine, even very old ones.

When controlling the fan, other input devices are also used: and a crankshaft speed sensor. Their readings are necessary to determine the operating mode of the electric motor. The signals from all sensors are transmitted to the electronic control unit, which, after processing them, activates the relay for turning on the engine cooling fan and regulates the impeller rotation speed. Fan with thermal switchOlder systems did not have an electronic control unit, and the function of turning on / off the electric motor was performed by a so-called "thermal switch", which is often mistaken for a temperature sensor. In fact, a "real" temperature sensor is almost always installed in the case. It is from it that a signal is sent to the scale in the cabin, since the temperature in the immediate vicinity of the combustion chamber is more important for measurement. The thermal switch also reacts to an increase in the coolant temperature (but in the radiator). It is calibrated to a certain temperature (for example, 85 and 70 degrees Celsius) - to turn on and off. If the temperature exceeds a preset threshold, contacts inside the thermal switch close, closing the fan power circuit. The electric motor, which is energized, starts to rotate the impeller. As soon as the temperature has dropped to the lower threshold, the contacts open and the fan stops.

Engine cooling fan operation

A defective engine cooling fan will inevitably cause the engine coolant temperature to rise. If you notice, you can stop and check the fan operation yourself.Electric fans are installed both on the outside of the radiator and on the side engine compartment... There is no consensus among engineers about the advantages of a particular installation

To diagnose an "analog" fan, just lift the hood and look at the impeller blades. The fan on the viscous coupling always moves, therefore, if you observe rotation, the cause of overheating is most likely a breakdown of another component of the cooling system, for example, a thermostat. A sign of failure of the viscous coupling may be too low speed rotation of the fan at high speed. electric fan cooling, and you see that it does not work with obvious overheating, use the following method: disconnect the connector from the thermal switch, which is usually screwed into the bottom of the side tank. Taking the connector in your hands, use a small piece of wire to close the 2 sockets of the plug. In this case, the fan must start forcibly.This method cannot be recommended to owners of the most modern cars with electronic device fan speed control. The most the owner can do is check the integrity of the corresponding one. Further diagnostics should be entrusted to professionals.

Internal combustion engine cooling systems have split into two branches during their development: air cooling and liquid cooling. The system liquid cooling it is more correct to call it a hybrid, since the fan is used in both types of systems. A medium for dissipating excess heat in the process of removing it from a heated power plant air comes out. The cooling fan is a device that ensures stable and uniform heat dissipation to the environment.

The hybrid cooling system has almost completely replaced the air cooling system in the design of production cars, so further we will talk exclusively about it. It is also worth noting that the fan function in both systems is the same. Cooling fan forcing efficient airflow to the engine and radiator of the hybrid fluid system cooling.

The fan serves for better cooling motor and fluid in the radiator. This effect is achieved by blowing and increasing the flow rate and the total mass of air that passes through the cells and fins of the radiator. In most cases, the fan is installed in the space between the radiator and the power plant. The radiator fan itself is enclosed in a special casing.

Radiator fan device

A car fan has at least four blades that are mounted on a single common pulley. The blades are located at a certain angle relative to the plane of rotation. This is done to maximize air intake and subsequent delivery. There are no rigidly established patterns in the fan design, although such a design has become the most common, which includes an impeller with 8 blades.

Drive variations

The radiator fan may vary in drive design. The existing types are divided into:

- mechanical;

- hydromechanical;

- electric;

Mechanical drive

Such a drive is a structure that is essentially a permanent drive from the crankshaft of the power plant. Such a drive is the simplest and is realized using a belt drive. The main disadvantage of the mechanical drive is the power take-off from the unit, which is spent on ensuring constant fan rotation. Today, the mechanical drive is practically not used in cooling systems on civil cars.

Hydromechanical drive

This type of drive is a solution that is realized by installing a viscous coupling (viscous coupling) or a hydraulic coupling. These clutches are permanently driven by the engine crankshaft. In order to keep the fan blades intact when iCE operation on maximum speed and high speed of rotation of the crankshaft, the fan impeller is connected to the pulley by means of a hydro or viscous clutch. There is also a definition of thermal couplings, which is applicable depending on the design features.

The clutch can be partially or completely blocked due to the increasing temperature of the fluid with which it is filled. This filling fluid is silicone. The increase in temperature occurs as a result of an increase in crankshaft speed and an increased load on the engine. The clutch is locked and the cooling fan starts rotating. The hydraulic clutch differs in principle from the viscous clutch and is blocked depending on the amount of oil that is in the clutch.

It turns out that the viscous coupling is often filled with silicone gel, which has the ability to change its properties under the influence of temperature. Silicone oil is poured into the coupling in an amount of about 30 or 50 ml. The clutch lock affects the fan speed regardless of the engine speed. If the power unit enters the mode high revs, then the clutch slows down the rotation of the impeller, thereby protecting the fan from destruction at high rotation speeds. The main task of all types of couplings, which differ in the principle of operation and design features, is to keep the fan speed within a strictly limited range. The viscous coupling provides the speed range required by the impeller for the most efficient cooling.

As mentioned, mechanically driven fans have become rare but have not completely disappeared. Such a device can still be found on some car models that have a longitudinally located power unit. Another segment of cars in which the installation of a fan with a similar type of drive is widespread and justified is powerful SUVs. Such machines are able to overcome water obstacles and are prepared for operation in extremely high humidity... The fact is that any electronics fail after contact with water, and viscous couplings are completely sealed devices and are not afraid of moisture.

Electric drive

Active development and implementation of electronic control and monitoring devices different systems in the process of engine operation led to the appearance of an electrically driven radiator fan. This drive has a separate electric motor and its own control system. The controller allows you to set the intensity of the impeller and flexibly change the speed and duration of the fan rotation based on the temperature sensor readings. The sensor measures the temperature of the engine coolant. This solution not only increased efficiency, but also made it possible to achieve improved uniformity of engine cooling compared to systems based on the use of viscous coupling.

Electric cooling fan

The fan motor is powered from the on-board network vehicle... The existing solutions should be divided into:

- fan with thermal switch;

- fan with electronic unit;

Cars at an early stage structurally did not have electronic control units. The activation and deactivation of the electric motor of the cooling fan was performed by a thermal switch, which some motorists confuse with a temperature sensor. The temperature sensor is often built into the engine block housing. Signal on dashboard in the cabin comes from him, since temperature control near the combustion chamber is much more important than the coolant temperature.

The thermal switch is similarly activated when the temperature rises, but relies on the readings of the coolant temperature sensor in the radiator. The device operates in a narrow temperature range. For example, the fan is activated at a coolant temperature of 85 degrees Celsius, and it will turn off at 70 degrees. The principle of operation of the device is quite simple. If the temperature rises above the set threshold, then the contacts in the thermal switch close, which will lead to the closure of the cooling fan power supply circuit. A current is supplied to the electric motor, the impeller begins to rotate. Lowering the temperature to the minimum threshold will cause the contacts to open and the fan will stop working.

It is noteworthy that the design of the fan electric drive with a thermal switch can be installed on almost any motor. The fan control circuit is much more complicated in modern models with and includes a number of elements and actuators, including the main ones:

- coolant temperature sensor;

- fan on relay;

- electric motor;

A temperature sensor measures the temperature of the coolant in the power unit. Modern cars can have two sensors at once, which are installed in different places. One thermal sensor is placed at the outlet of the motor or in the thermostat housing, the other is placed in the branch pipe at the outlet of the radiator. The fan is controlled taking into account the readings of both elements and the subsequent assessment of the difference in the data that comes from the sensors. For more effective management, also involved additional devices, among which it is worth noting the crankshaft speed sensor and. The readings of these sensors are necessary to accurately determine the mode in which the engine is operating at a particular moment.

The set of signals from the sensors is transmitted to the engine ECU, which analyzes them and activates the fan relay at the right time. The fan works exactly as long as it is necessary to achieve the optimal temperature indicator in relation to a specific speed and load on the internal combustion engine.

Car models that have climatic installationoften get two fans at once. Each of these fans has a separate switching circuit. The fans can work synchronously or separately, which will directly depend on the temperature and operating conditions of the internal combustion engine. The fan relay is gradually replacing the dedicated fan control unit for the most efficient fan control.

There is also a function when implemented automatic switching on fan after the engine is turned off. This is necessary to prevent a too sharp rise in temperature immediately after stopping a heated engine, since as a result, the circulation of the coolant in the system immediately stops.

Common faults and diagnostics

Remember that it is worthwhile to diagnose a malfunction of the cooling system fan with extreme caution, as the rotating impeller can seriously injure your fingers or other parts of the body! It is not uncommon for a faulty fan to start moving unexpectedly!

Cooling fans are installed both in front of the radiator and behind it, on the side of the motor edema. There is no established uniform standard regarding the place of installation among designers. Many car owners also often wonder which direction the fan is blowing. It is believed that it blows the radiator for better coolant cooling. It is worth remembering that the fan blows exclusively on the engine, regardless of its location. Installation in front of a radiator does not mean that only the radiator itself is blown. Changing the blowing direction is not permissible.

Any electrical engine or viscous coupling of different power and production technology, as well as an electronic unit or a regulator designed for control, cannot provide a 100% guarantee of failure protection. The problem is aggravated by the fact that the failed cooling fan power unit will immediately entail serious consequences in the form of motor overheating. Even control devices, created to timely inform the driver at a critical moment, fail. It is necessary to monitor the condition of the fan and its serviceability with enviable regularity. On the move, it is also worth taking another look at the temperature gauge on the dashboard at the earliest opportunity.

Simpler thermal switch systems are easy to diagnose. As for modern cars, then it is very important to correctly determine not only the breakdown of the fan itself, but also to identify the failed element in a chain of several devices. At the very beginning of the diagnosis, you need to find the problem that caused the fan to stop working. Any of the sensors, the control unit or itself can fail. electric motor... It is quite possible to diagnose a malfunction on your own, following the recommendations below.

Power-driven systems are diagnosed quickly. Just watch the fan, which should be spinning constantly. If you see spinning and the impeller blades are intact, then look elsewhere for the problem. Engines with a viscous coupling overheat due to a faulty fan only if the coupling does not provide sufficient impeller blocking at high crankshaft speeds. The result is a low fan speed and airflow that does not match the load on the motor. Clutch failure can be determined by analyzing the fan speed at low and high speeds.

If the car has an electric cooling fan, then start by checking its operation. When the fan does not turn on due to obvious overheating, you can use the following method to diagnose systems with a thermal switch:

- you need to disconnect the connector of the thermal switch, which is often screwed into the bottom;

- then you need a little wire. Being careful, we use the indicated wire as a jumper, which must be used to close the 2 sockets of the disconnected connector;

If the fan is forced to work after such an operation, then the malfunction of the thermal switch is quite obvious. A non-working fan will mean a malfunction in it or in other parts of the circuit. The design can also consist of a double temperature sensor. The check should be done in two stages, although the principle remains the same. At the very beginning, the first two contacts are closed, after which the fan should rotate at low speed. Then the second pair is closed, after which the rotation speed should increase noticeably.

It also happens that the radiator cooling fan blows constantly, without visible pauses. These symptoms are common. This may indicate a failure of the inclusion sensor. The check should be carried out with the ignition on by further removing the corresponding connector from the sensor. If the fan does not turn off after that, then the shutdown regulator should be replaced. Additionally, you can perform a fuse check if the problems with the cooling fan performance have not disappeared.

The main thing to remember is that, as in any other electrical circuit, it is worth diagnosing the malfunction of individual component parts elimination method. The condition of the wiring, connectors and plugs will require no less attention. In some cases, the breakdown is quickly eliminated thanks to simple repair cable that requires insulation, as well as cleaning the contacts. Replacing the plug can be just as productive. If, after all the diagnostic procedures, the fan still does not work, then it must be dismantled and replaced.

The above methods cannot be recommended to those car owners who have a car with an electronic device for controlling the rotation speed of the cooling fan. An inexperienced driver on his own can only check the serviceability of the fuse, which is responsible for this area. Then you need to contact a car service for help.

Prevention, removal and repair

Ensuring the most efficient cooling of the internal combustion engine and radiator is possible only when the fan is periodically cleaned, and minor breakdowns and contamination are eliminated. It is advisable to carry out such a check at least once a year. The fan is cleaned with a regular brush, which removes dirt and dust from it.

If it was necessary to dismantle the cooling fan, then:

- disconnect the ground wire from the battery;

- disconnect all connectors that are connected to the device,

- unscrew the casing fastening bolts;

- slide the fan shroud or dismantle the assembly;

Removing the fan allows you to eliminate most of the breakdowns through repair. Very often it is necessary to strip or replace the wires, since their broken contact becomes the cause of malfunction or deviations from the norm during the operation of the fan. It may be necessary to repair the brushes, which means replacing them. The specified element fails more often than others. Brushes are subject to rapid wear as they collect dirt from the road.

It is not uncommon for it to be necessary to eliminate a short circuit or break in the rotor winding. It happens that the winding is in working order, but the functionality is still impaired due to the abundant accumulation of dirt. This problem is solved by cleaning the windings with a solvent. Special brushes designed for deep cleaning are also suitable.

In the course of operation, there are also cases that will require replacement of the electric motor. The malfunction often manifests itself on a warm engine, the whole circuit is working, but the cooling fan does not start. As practice shows, it is impractical to repair this part. The electric motor has an acceptable cost, so that it is immediately replaced with a new one.